Advantages of bevel gear boxes

High efficiency:

Bevel gear boxes are very efficient and have exhibit only low losses due to friction or heat generation. This makes them the preferred choice for applications requiring the transmission of large amounts of power.

High load capacity:

Bevel gear boxes are able to withstand high loads and offer higher load capacity compared with other gear boxes. This makes them the preferred choice for applications requiring high torque.

Precision:

Bevel gear boxes offer higher precision than other types of gear boxes. They can be used at high speeds and are able to maintain a constant gear ratio, which is important in many applications.

Flexibility:

Bevel gear boxes can be used in a wide range of applications because they offer a broad spectrum of gear ratios and can adapt to various power and torque requirements.

Long service life:

Bevel gear boxes are robust and long-lasting. They can be operated for years without major maintenance and are capable of handling high stresses and loads.

Disadvantages of bevel gear drives

Lubrication:

Bevel gear boxes require appropriate lubrication to achieve optical performance. Insufficient lubrication can result in premature wear or damage to the gear box.

Noise:

Bevel gear boxes can emit relatively high noise levels due to contact between the gears. This is undesirable in some applications.

Maintenance:

Bevel gear boxes generally require regular maintenance to ensure optimal performance and a long service life. All bevel gear boxes from Ganter are encapsulated in an aluminum housing and protected against the ingress of dust, making them maintenance-free since they have a lifetime supply of grease.

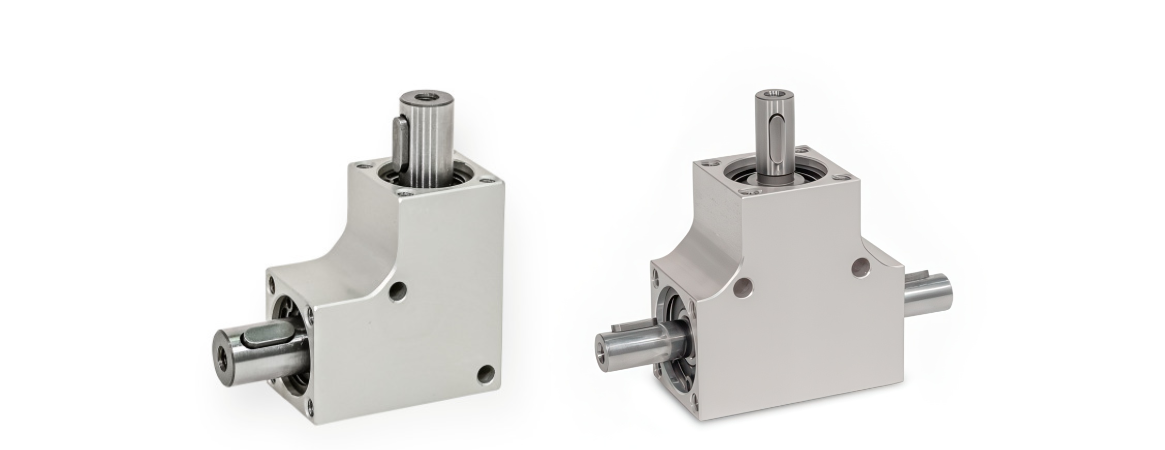

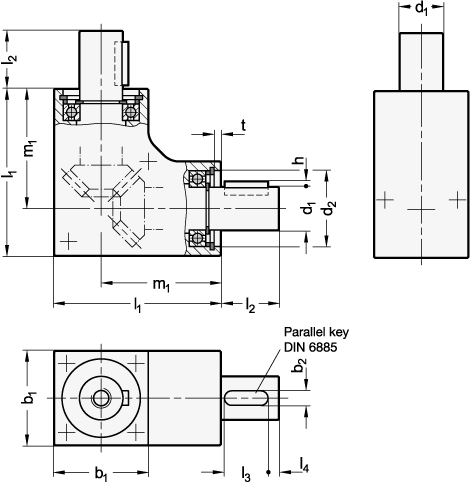

Structure of bevel gear drives

A bevel gear box consists largely of a driving bevel gear engaged with a driven bevel gear. The gear teeth have a conical shape and are designed to make contact at the tips.

The bevel gear teeth can be either a straight or inclined. In a straight bevel gear design, the gear teeth are straight and converge along the cone surfaces.

The bevel gears are situated within a housing. This housing protects the gear box and keeps it in position.

Bevel gear drives from Ganter are available with many fastening holes for easy installation in any situation.

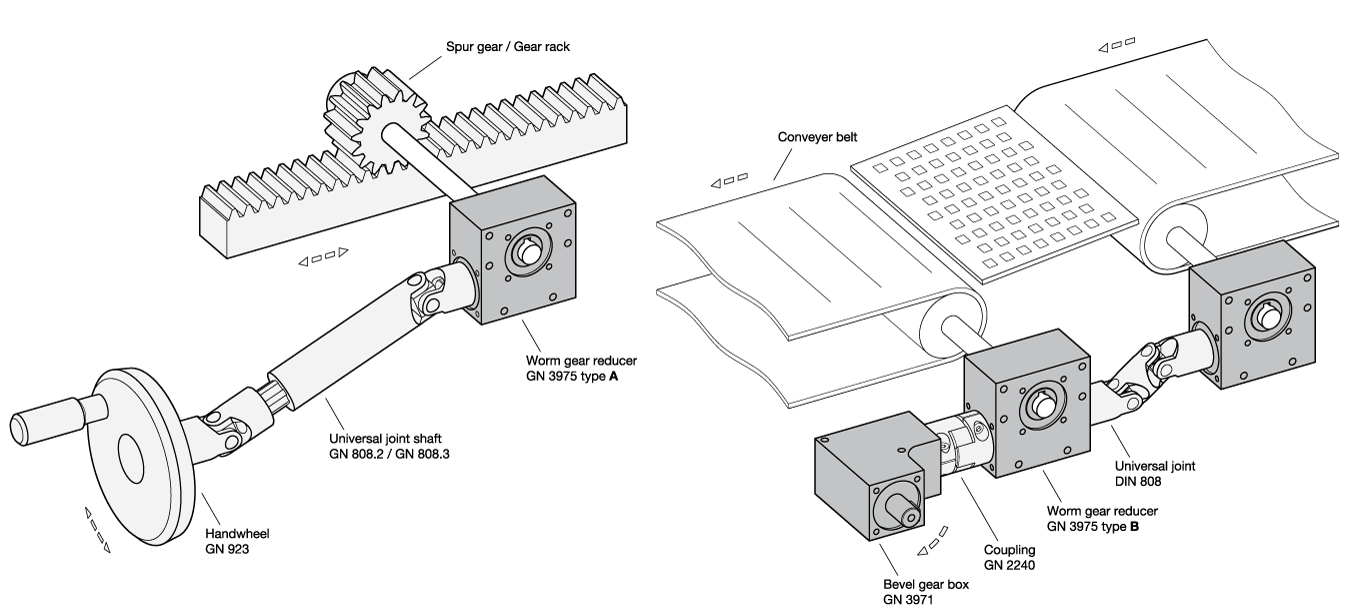

Application examples