Advantages of Ganter drill bushings at a glance

- Maximum precision for drilling processes

- Long service life thanks to hardened steel (HRC 62 ±2)

- Immediate availability – high stock levels

- Many different versions to suit every application

- Individual advice from our experts

What is a drill bushing?

A drill bushing – also called a drill guide sleeve – is a cylindrical guide element that is installed in jigs or drill fixtures for precise guiding of dill bits or cutting tools.

They are generally made of hardened steel that is wear-resistant and long-lasting even under heavy loads.

Types of drill bushings

Ganter offers a variety of drill bushing types for diverse requirements:

- Fixed drill bushings: Permanent installation for precisely repeatable drilling operations at a fixed position.

- Exchangeable drill bushings: Fast swapping for changing drill bit diameters – ideal for flexible manufacturing processes.

- Screw-in drill bushings: With thread for direct installation in fixtures – easy to install and replace.

- Adjustable drill bushings: Variably positionable for changing drilling patterns – maximum flexibility for complex parts.

Standard drill bushings from Ganter

| Type | Special features |

|---|---|

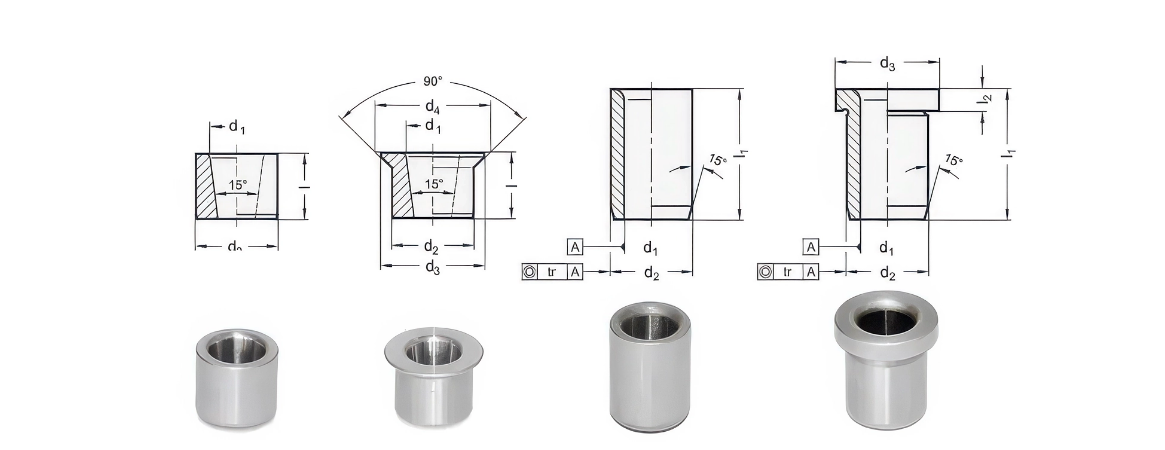

| Guide bushing DIN 172 | With collar, precision-machined fit sizes, bore rounded on one side |

| Guide bushing DIN 179 | Without collar, identical specifications as DIN 172 |

| Guide bushing GN 172.1 | With conical bore and collar |

| Guide bushing GN 179.1 | With conical bore, without collar |

Selecting the right drill bushings

Select the right drill bushing based on the following criteria:

- Material: For demanding applications, we recommend hardened steel.

- Bore diameter: Must fit the tool exactly.

- Installation type: Depending on the application – fixed, exchangeable, adjustable or screw-in.

- Standards & fit sizes: For optimal compatibility with your fixtures.

Application areas of our drill bushings

- Automotive industry: Precise drilling in engines, transmissions, car bodies

- Aerospace: For components with the highest tolerance requirements

- Medical equipment: For surgical instruments and devices

- General machine building: Universally suitable for tools and components

Why drill bushings from Ganter?

- Precision: Exact drilling – even at high part volumes

- Repeatability: Consistent quality over many cycles

- Long service life: Robust materials and quality-tested manufacturing

- Cost savings: Lower scrap rate, less tool wear

Order drill bushings from Ganter today

Standard products or custom orders – Ganter can supply you with the right drill bushings for every application. Trust in our many years of experience and custom-tailored solutions for your production.

Contact us for personal advice or browse the online catalogue directly!